Morris Lubricants launches fuel efficiency calculator

Morris Lubricants has launched a fuel efficiency calculator, which it says can demonstrate to clients in the heavy duty diesel market the savings and benefits that can be achieved by using low viscosity high performing engine oils.

Morris Lubricants has launched a fuel efficiency calculator, which it says can demonstrate to clients in the heavy duty diesel market the savings and benefits that can be achieved by using low viscosity high performing engine oils.

By entering details about their current consumption – including the number of vehicles in their fleet, annual mileage, oil sump size, oil drain interval, fuel usage and diesel cost – the calculator will forecast the financial and environmental benefits that a customer could expect by upgrading to one of the lower viscosity oils produced by Morris Lubricants, such as 5W-30.

“It’s important to realise we are talking solely about viscosity characteristics here, and not performance level,” said automotive product manager Adrian Hill, BSc.

“Any lubricant should be selected based on the performance level and viscosity specified by the manufacturer. This will ensure service intervals are reached and the components get the maximum level of protection.”

Available online, and in the Morris AR smartphone and tablet app, the calculator will display how much money could be saved annually.

It will then convert this figure into tangible assets that this amount could be spent on, such as the number of tyres or vehicle services, or how many extra miles could be gained, says Morris Lubricants – all of which are significant factors when calculating the future prosperity of a fleet.

“Any help we can give to our customers to save money is really useful,” said business development director Ian Douglas, who believes the digital tool comes at a useful time, as remote meetings continue to take place instead of face-to-face ones where appropriate due to Covid-19.

“To be able to show a customer how the use of modern, technologically advanced lubricants can make their fleet more efficient and add to their profits is really important. They are tested in the field, under real working conditions, and will also give greater protection to our customers assets.

“When someone is investing huge amounts of capital in their fleet, they need peace of mind when it comes to the lubricants they choose. The real advantage of this tool is that it shows how the different lubricants have an impact on their fleet and what real savings can be gained, such as how many tyres they could purchase with the savings.”

Recognising the need to reduce vehicle emissions in this sector, the Morris Lubricants fuel efficiency calculator also highlights CO2 savings.

To produce enhanced engine oils that to help achieve these savings, Adrian Hill says it’s necessary to look at how they behave on a molecular level, where friction reduction takes place.

“If we look at the oil film generated between bearing faces and journals, compression rings and liner, for example, a certain ‘thickness’ is required to keep these components apart,” Adrian explained.

“15W-40s and 10W-40s for example, generate a nice lubricant cushion which protects bearings, and maintains a good seal between ring and liner – but energy is expended moving the oil through these lubrication areas.

“This energy burns additional fuel, which in turn increases CO2 output. So, as we move to 5W-30s, a thinner oil film is generated, reducing internal ‘drag’ and making the most of the energy generated in the combustion chamber to drive the wheels, and of course produce less CO2.”

The Morris Lubricants fuel efficiency calculator can be accessed at: https://fuelcalculator.morrislubricants.co.uk or by downloading the Morris AR smartphone and tablet app via the app store.

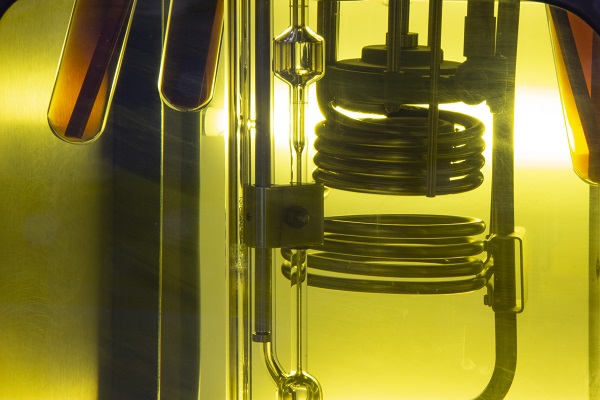

The company has also detailed recent equipment upgrades at its laboratory.

The company has also detailed recent equipment upgrades at its laboratory.

“As lubricant specifications move on and become more complex, they often dictate new test methods which require new equipment,” said Andy Litchfield, who in his role as technical director oversees the laboratory and technical teams, who work together on research, new formulations and day-to-day testing.

“The Morris family have always purchased what is required because product quality is key to the success of the company, and without the correct test equipment you cannot guarantee the highest quality. Their support allows us to keep up to date and compliant with new and evolving demands.”

With a combined cost of approximately £75,000, recent upgrades include a new Fourier Transform Infrared Spectrometer (FTIR), which is used to identify organic materials; and an X-Ray Fluorescence (XRF) machine which measures elemental content, thereby helping the team ensure they are adding the correct amount of performance additive, which often contain elements such as calcium or zinc.