Tyre handling technology from Tecalemit

Tecalemit Garage Equipment provides a range of specialist commercial vehicle tyre handling tools to enable workshops to handle the demands of large, heavy wheel and tyre combinations.

Tecalemit Garage Equipment provides a range of specialist commercial vehicle tyre handling tools to enable workshops to handle the demands of large, heavy wheel and tyre combinations.

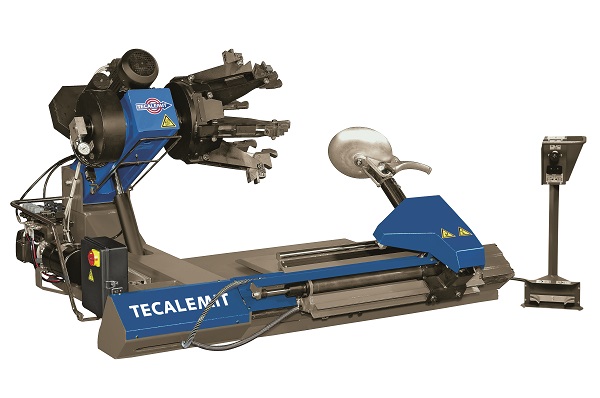

The Tecalemit range of CV tyre changers offers a choice of seven machines, ensuring that the specific vehicle fleet requirements can be accommodated.

The TCS26 model is designed to be operated with truck wheels up to 26” diameter. The unit features fully adjustable pressure in order to carefully handle light alloy wheels. The tool trolley, lifting arm and four-jaw universal chuck are controlled by a hydraulic system. With a small space-saving footprint, the unit is said to be ideal for workshops where space is at a premium, with simple operation via a wired remote control.

Capacity can be further increased with the Tecalemit TCS52 series. These units increase the clamping capacity up to 40”, with 60” achievable with an extension kit, and feature a bead breaking force of 3.7 tons to handle both CV and agricultural applications. Retaining all of the adjustable features of the TCS26 model, the TCS52 series utilises a double speed rotation chuck for extra control.

As the wheel size is increased, additional load is placed on the wheel clamping system. Tecalemit’s TCS56 series introduces a six-jaw clamping mechanism, together with a wireless remote control option for even easier operator use.

For the utmost in wheel capacity, the Tecalemit TCS60 series introduces a 2,900mm tyre diameter and a wheel weight of 2,800kg to handle the largest of off-road vehicles. With an increase in hydraulic motor capacity to 3.5hp, it is said to handle even the most demanding of wheel and tyre combinations with ease.

Once the tyre is fitted to the rim, some thought needs to be given to inflation safety, says the firm, since a burst tyre can cause significant operator injury.

Once the tyre is fitted to the rim, some thought needs to be given to inflation safety, says the firm, since a burst tyre can cause significant operator injury.

The Tecalemit tyre inflation cage is said to provide an effective solution. It can accommodate all types of CV wheels, but can also be used for car and light commercial van tyres. The tyre inflation cage features a special perforated mesh enclosing structure to minimise the shock wave that might be generated in a tyre burst situation.

Operator safety can be further improved with the optional electronic inflating system, adds Tecalemit. This enables the operator to deploy a standalone inflation process. The required inflation pressure is set, enabling the pressure gauge to control the operation unassisted, leaving the operator free to carry out other tasks.

The tyre inflation cage can also be equipped with a blast inflating system to assist with the fitting of tubeless tyres. The side opening of the inflation cage allows this operation to be carried out easily inside the inflation cage, says the firm, with no reduction in operator safety.

With the tyre successfully fitted to the rim, the final wheel balancing operation can be completed. The Tecalemit TBM 855/V955 Universal Wheel Balancer is an electronic unit designed to operate on truck, bus, car and motorcycle wheels. It is supplied with a range of truck, van and car adaptors.

The unit features a double rotation speed together with a range of fifteen programs to accommodate both steel and alloy wheels with balancing modes for truck, van, car and motorcycle.

The menu-guided function keys for data entry and program set-up enable the operator to select from four dedicated truck modes, nine car modes and two motorcycle modes. A pneumatic lifting mechanism allows easy clamping of heavy wheels up to 160 kg.

The menu-guided function keys for data entry and program set-up enable the operator to select from four dedicated truck modes, nine car modes and two motorcycle modes. A pneumatic lifting mechanism allows easy clamping of heavy wheels up to 160 kg.

The operator can use the digital display to select a split weight program and static unbalance optimisation program before commencing the automatic measurement cycle.

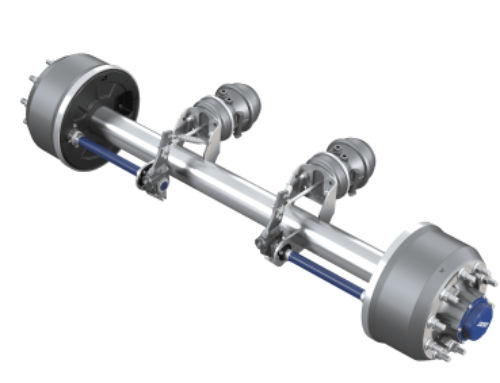

With the vehicle tyres fitted safely and efficiently, the final step is to ensure the vehicle geometry is correctly set in order to maximise tyre life and reduce unnecessary fuel consumption.

The Axis500 is the latest commercial vehicle laser wheel alignment system from Tecalemit. Cited benefits include easy setup, and the ability to align a tractor unit in as little as 20 minutes. All measurements are taken in the as-driven position. Because the vehicle is driven onto heavy-duty turn-plates, there is no need to lift the axles to perform run-out compensation, adds the company.

Measurement includes all the important angles; toe, camber, toe out on turns, caster, kingpin, axle off set, axle parallel and chassis to axle square are all covered. The latest in electronic digital inclinometer technology means no more calculating castor, adds the firm. An immediate readout from the Tecalemit AXIS500 electronic/digital inclinometer provides the vehicle technician with instant results.