HJS retrofits help LCV fleets cut emissions

HJS Emission Technology has developed a retrofit selective catalytic reduction (SCR) exhaust system for light commercials, which it says offers fleet operators a cost-effective means of complying with the latest emission standards at the fraction of the cost of replacement vehicles.

HJS Emission Technology has developed a retrofit selective catalytic reduction (SCR) exhaust system for light commercials, which it says offers fleet operators a cost-effective means of complying with the latest emission standards at the fraction of the cost of replacement vehicles.

HJS highlights the planned introduction of clean air zones (CAZs) across the UK aimed at improving air quality and thereby public health, including by reducing nitrogen dioxide and particulate matter (PM).

“The UK’s most immediate air quality challenge is to bring roadside concentrations of nitrogen oxides (NOx) within legal limits in the shortest possible time,” said HJS.

“This is being implemented through the National Air Quality Plan which requires the majority of vehicles travelling within the zones to meet exhaust emission standards for NOx and PM or pay a daily charge. If a vehicle does not meet the required standards and the daily charge is not paid, a penalty notice charge will be issued to the operator/owner.

“These tighter new emission standards require all diesel-powered vans and minibuses to comply with Euro VI emission standards in order to operate freely within these zones.”

The retrofit HJS SCR system offers ULEZ/LEZ and CAZ compliance for a large range of Euro V light commercial chassis applications, including the Ford Transit, Mercedes-Benz Sprinter and Vito, Volkswagen Crafter and T5, Vauxhall Movano, and Renault Master, among others.

Mark Cooper of HJS UK said: “HJS have already retrofitted hundreds of UK buses with SCRT technology upgrading emissions to Euro VI standards. The cost of replacing fleet is a huge expense and HJS can upgrade vehicles at the fraction of the cost of buying a replacement vehicle.

Mark Cooper of HJS UK said: “HJS have already retrofitted hundreds of UK buses with SCRT technology upgrading emissions to Euro VI standards. The cost of replacing fleet is a huge expense and HJS can upgrade vehicles at the fraction of the cost of buying a replacement vehicle.

“The van market is a new exciting business area for us here in the UK and we are ahead of our competitors in this market.”

Euro V light commercial vehicles are already equipped with a DPF system for the reduction of particulate matter, and this element of the exhaust system is retained, says HJS.

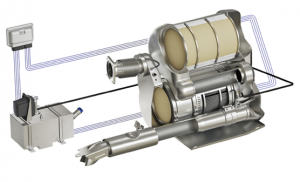

The SCR system supplied by HJS consists of an additional underfloor catalyst, an AdBlue tank, engine sensors and an independent control unit. The SCR system operates by injecting AdBlue directly into the exhaust gas stream, which mixes with the dirty exhaust gases converting nitrogen dioxide emissions into harmless water and nitrogen.

“The system is manufactured to the highest German quality standards and will be certified imminently for these applications in order to meet all of the requirements set out by the Energy Savings Trust’s Clean Vehicle Retrofit Accreditation Scheme (CVRAS) and the ULEZ in London,” said the firm.

“Our specialist team have over 30 years’ experience in the manufacturing and development of exhaust after-treatment systems. SCR technology has been installed to thousands of vehicles worldwide helping to reduce harmful emissions in towns and cities.”