Rymec’s CV clutch kit range

Rymec offers a portfolio of over 400 clutch kits for light and heavy commercial vehicles, covering vehicles from five to over 20 years old.

Rymec offers a portfolio of over 400 clutch kits for light and heavy commercial vehicles, covering vehicles from five to over 20 years old.

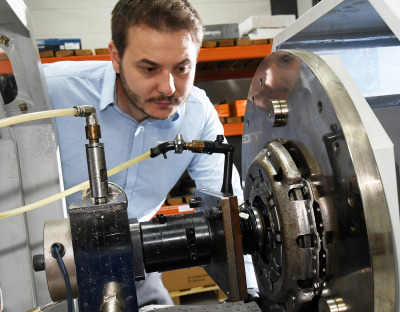

“All of these are manufactured to Original Equipment (OE) specifications and 100 per cent new,” said Rymec’s lead product manager, Ian Scobie.

“No component is remanufactured, and all of our kits are assembled in our dedicated UK facility.

“Our range includes two-piece kits and a large range of three-piece kits with either standard release bearings or concentric slave cylinders included in the box.

“However, with the two-piece kits we would encourage the installer as best practice to always replace the concentric slave cylinder at the same time. The description on the box will tell you if it is a two or three-piece kit.

“So, two-piece clutches are made from two key components, the cover assembly and the driven plate, these can also be known as a clutch pressure plate and clutch disc.

“The rotational speed and compression loads placed on a clutch can be immense and there are some key performance characteristics that are vital to the lifetime performance of the clutch. So, we want to give you a few examples of what we do to ensure our clutches perform to OE specifications.”

Ian explained: “If we take the cover assembly, it is basically a pressure plate and diaphragm spring that clamps or releases the driven plate from the flywheel. In essence, this temporarily disconnects the transmission from the engine, allowing a gear change to be performed by the driver.

“The diaphragm spring is heat treated to ensure the correct tensile strength under extreme load throughout its lifetime. The pressure plate is made from cast iron for its good thermal properties which gives a prolonged service life.

“The diaphragm spring is heat treated to ensure the correct tensile strength under extreme load throughout its lifetime. The pressure plate is made from cast iron for its good thermal properties which gives a prolonged service life.

“The key performance characteristics of the cover assembly are mapped against the OE performance characteristics to ensure Rymec product performs to original equipment specification.”

For the driven plate, says Ian, the friction material is made to OE grade specification to ensure matching OE performance.

“We carry out a burst test which is a test where we run the clutch for five minutes at one and a half times the engine’s maximum rpm, at 2500C. The clutch is then tested to ensure it operates under normal tolerance levels against all our other tests and matches the OE performance and characteristics.”

Another important element is the hub, he adds. This is heat treated to withstand the high loads encountered during its lifespan.

“Some hub designs incorporate rotational free play which is called a floating hub and is specifically designed like this, and it is not a product or manufacturing defect.

“Some hub designs incorporate rotational free play which is called a floating hub and is specifically designed like this, and it is not a product or manufacturing defect.

“We would also like to mention the design differences between Rymec and other clutch manufacturers. They may not always look exactly the same; the most obvious differences might be in the cover pressing design where different methods of manufacture have been used.

“Despite these differences, you can be confident we have specified the right part for the right application and where the differences are obvious, we include a technical bulletin within the box reassuring your customer that it is correct for application.

“Every Rymec clutch kit is supplied with spline grease; we recommend the installer uses this, as we often hear of cases where copper-based or another non-approved grease being used which can cause premature failure of the clutch.”