Fras-le issues troubleshooting guide for brake drums

Frasle Mobility-owned commercial vehicle (CV) braking supplier, Fras-le, has issued its latest troubleshooting guide, designed to help identify common problems that may occur in brake drums.

A regular and thorough inspection of brake drums is very important to the proper operation of the braking system and should be included in fleet operators’ regular maintenance checks, says Fras-le.

Cracked drum

“Upon inspecting the drum, if a crack has been discovered that extends through the entire wall, this condition is caused by excessive heating and cooling of the brake drum during operation,” said Fras-le.

If this fault is discovered the drum must be replaced immediately, warns the braking specialist.

“Repeated cracking of the drums may indicate either a brake system fault or driver abuse. If this problem occurs, close attention must be paid to the brake system balance and brake lining friction ratings as specified by the original equipment manufacturer (OEM).”

Grease stained drums

“If this condition is apparent, the brake drum will show discolouration on the braking surface. This condition is normally associated with a faulty lubrication system or improper greasing of the brake cams.

“Once the source of the contamination has been identified and remedied, thorough cleaning of the components must be carried out, and any contaminated brake linings must be replaced.”

Polished brake drums

Polished drums can be identified by a mirror-like finish on the braking surface, says Fras-le.

“This problem can be remedied by lightly sanding both the lining and brake drum surface with some medium grit emery cloth.

“The brake system should be checked for lightly dragging brakes and the linings should be checked to ensure the correct material is being used.”

Fras-le recommends that the braking surface is sanded each time the linings are replaced.

Broken mounting ring

“This problem occurs when there is interference between the hub and drum mounting surface, due to incorrect seating of the drum on the hub during installation, a damaged hub or a build-up of corrosion on the hub.

“Prior to brake drum replacement the hub should be visually checked and any defects rectified, by either cleaning up the hub or replacing where necessary. If any cracks are identified in the bolt circle or mounting surface the drum must be replaced.”

Scored brake drum

“This problem is indicated by defined grooves in the braking surface of the drum and excessive brake lining wear. These grooves are caused by either the brake linings being completely worn out causing a metal-to-metal situation, or a foreign body finding its way inside the brake drum area.”

Radial cracking of mount surface

“This condition is caused by interference between the hub and drum mounting surface during installation as a result of using the wrong drum for the application or improperly cleaning the hub piloting surface prior to drum installation. If this condition exists, the drum must be replaced.”

Fras-le advises technicians to check the application to determine the proper drum for the application before attempting to install a replacement drum.

“The technician should then visually inspect the hub piloting surface and make sure that all the dirt and corrosion are properly removed. Care should be taken when installing the drum to make sure the mounting surface is properly and evenly seated against the hub mounting surface before torquing the wheel nuts during assembly.”

Heat checks

“Heat checking presents itself as a number of short, fine, hairline cracks on the braking surface of the drum. Heat-checking is a normal characteristic found in brake drums and is caused by constant cooling and heating of the braking surface, which occurs when the brakes are applied during everyday operation of the vehicle. Normal heat checking will not impair braking performance.

“Heat checks will ordinarily wear away and reform as a result of the normal braking process, however heat-checks may progress over time into more serious cracks, which will require the brake drum to be replaced.”

Martensite spotted drums

“This problem presents itself as hard, slightly raised dark coloured spots on the braking surface, with uneven wear. A significant

characteristic is a pulsating brake pedal, combined with excessive noise.

“This condition indicates that the drum has been subjected to extremely high temperatures. These extremely high temperatures have caused structural changes to occur in the brake drum material, which will make the drum more susceptible to cracking. If this condition exists, both the brake drum and linings must be replaced and the source of the overheating identified and remedied.”

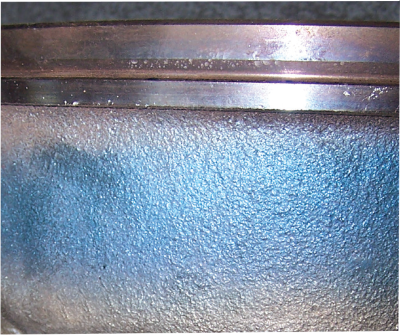

Blued brake drums

“This condition occurs when the drum has been subjected to extremely high temperatures. This may be caused by continued hard stops, by brake system imbalance, or faulty return springs. It is not always necessary to replace the drum as long as it is still within the tolerances for operation.

“To correct this problem the brake system should be checked for proper balance, the return springs should be inspected to ensure that they have neither become weak or broken and the brake shoe clearance should be checked and if necessary adjusted. If this condition is left unresolved it can result in either cracking or a martensite condition.”

Oval drums

“This issue exists when the drum diameter shows variations at different points around the braking surface and the brake linings exhibit more wear on one side than the other. This distortion of the drum as a result of excessive heat generated during brake applications or as a result of improper drum storage techniques.

“Other possible causes for this condition include improper chucking of the drum turning or it could be the result of dropping the drum on a hard surface during routine wheel-end maintenance.”

Excessive wear

If excessive wear occurs along the edges of the lining contact area of the braking surface or in area coinciding with the lining rivet holes, says Fras-le, the system should be checked to make sure that there is not an abnormal build-up of abrasive material.

“The most common cause of this problem is the build-up of abrasive material from either the presence or the absence of dust shields depending on the application of the vehicle.

“If the problem occurs while dust shields are installed, the technician should remove the lower dust shield to allow abrasive materials to more readily exit the braking system. If the problem occurs while dust shields are not employed, install dust shields to restrict abrasive materials from entering the brake system. Brake drums should also be checked for evidence of scoring.”

Fras-le advises technicians to follow best practice when performing regular braking maintenance checks to ensure they are covered by warranty.

More information on the Fras-le brand is available at the website.