On the road again

BPW offers its perspective on fault diagnosis for trailer braking systems

Demand for efficient transportation continues to surge, and the reliability of trailer braking systems becomes paramount. Trailers bear the weight of commerce on their axles, and even the most robust trailers can face braking system challenges.

The Technical Services team at BPW Limited is available to assist in diagnosing issues with trailer braking systems.

Problem causes can be largely split into three: the foundation brake (disc or drum), the trailer brake control system – EBS (Electronic Brake System) – and the towing vehicle.

A comprehensive understanding of these areas is necessary to make fault diagnosis and rectification less challenging.

Foundation brake issues

Often, the clues to the cause of a problem lie in the condition of the friction material (brake linings or pads) or the friction surfaces (drums or discs). Whilst symptoms may appear similar, it must be borne in mind that, as disc brakes run hotter than drum brakes, these symptoms will vary across the two.

Mechanical checks will ensure that the physical setup of the brake is still functioning as expected.

Case 1: annual MOT test and brake performance failure

A trailer is presented for the annual MOT test and fails on brake performance. The driver has not reported any braking issues, so the first step is to assess the condition of the friction material or surfaces.

In most cases, it will be seen that either the brake linings or pads exhibit very little wear for the mileage that the vehicle has covered, and the drum or disc has a sheen on the surface. This is a classic case of brake under-utilisation, sometimes referred to as glazing. With retarders on most modern towing vehicles, this is a common problem. With EBS, the towing vehicle has control of the braking balance between the tractor and trailer. Sometimes adjustments can be made on the trailer’s EBS, but very often the remedy lies in liaison with the towing vehicle manufacturer to get them to adjust it to the tractor EBS.

Understanding MOT test anomalies

Why would poor braking performance occur at MOT time when the driver has previously not complained about poor braking? The answer lies in the understanding of the braking pressure.

Pressures in the braking systems on the tractor and trailer are referenced to the pressure in the yellow service connection (coupling head) between the two, as it is the only point common to both systems, referred to as ‘coupling head pressure’ (‘Pm’).

When driving normally, the brake pressure delivered to the brake chambers is below 2 Bar ‘Pm’ for 90 per cent of the brake applications. Even when performing an emergency stop, the pressure rarely exceeds 4 Bar ‘Pm’.

During a roller brake test (RBT), the pressure can reach as high as 8 bar ‘Pm’. Air pressure is directly proportional to friction surface pressure, and it is at these higher pressures that an under-utilisation effect and contamination of friction can become apparent. Guidelines requiring laden roller brake tests at each safety inspection have also affected the testing process. With this additional load, achieving a pass simply on ‘wheel locks’ is harder to achieve, and brake performance problems become more apparent.

BPW see cases where the vent plug bungs have not been removed from the brake chambers. This is especially troublesome with disc-braked axles, but also causes problems with drum-braked axles. Depending on which plugs have been left in place, there can be two issues:

(a) Pressure can be retained in the low-pressure housing, causing a binding brake.

(b) There can be a residual vacuum in the housing that has to be overcome by air pressure before the brake can be applied. In this latter case, it will manifest itself as under-utilisation.

Note: sometimes the bungs might be left in on only one or two-wheel stations, causing the problem on those corresponding brakes.

Under-utilisation, as well as other brake performance issues, can be identified with the use of BPW’s EBPMS (Electronic Brake Performance Monitoring System) allied with BPW’s idem Telematics, giving operators advance warning and the opportunity to plan service and maintenance before brake performance becomes an issue.

Case 2: routine brake re-lining

A telephone call may be received by the BPW Limited services and support team from a customer complaining of poor brake performance issues. The trailer is two or three years old, and in these cases, the problem has usually been reported by the driver. The clue is that the brakes have performed well so far. The customer is asked what has changed. For example, is there a new driver or new towing vehicle, or is the trailer being used for different types of work? The normal response is that “nothing has changed, although we re-lined the brakes a little while ago.”

BPW’s brake linings and pads are balanced with the metallurgy of the friction surfaces, and any deviation in these two components can cause problems. It is important to note that during the manufacture of a trailer, a brake calculation is generated using the known parameters of the original equipment specifications of the friction materials.

Further investigation into Case 2 revealed that non-genuine linings had been fitted, and this impacted the brake balance.

Brake calculation

BPW Limited offer a brake calculation service to trailer builders. These calculations are submitted with type approval documents.

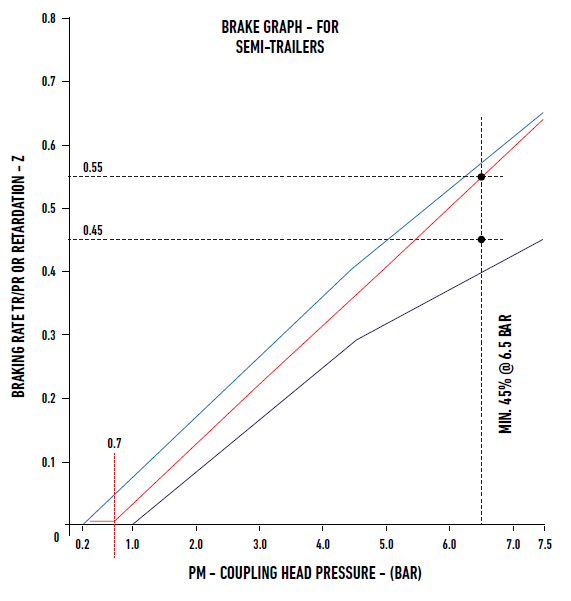

During calculations, variables such as wheelbase, centre of gravity, height, weight, and tyre size are all considered. The calculation produces a graph of retardation versus coupling head pressure. If you look at the typical graph for a semi-trailer in Fig. 1, you will see that the performance curve (the red line) lies between two blue lines which form an upper and lower bound. These blue lines are referred to as the braking corridor. For semi-trailers, the brake performance at 6.5 bar ‘Pm’ must be a minimum of 45 per cent (0.45g).

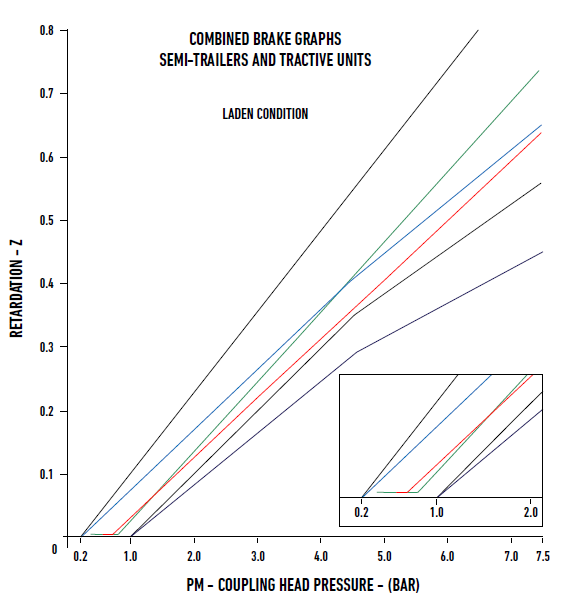

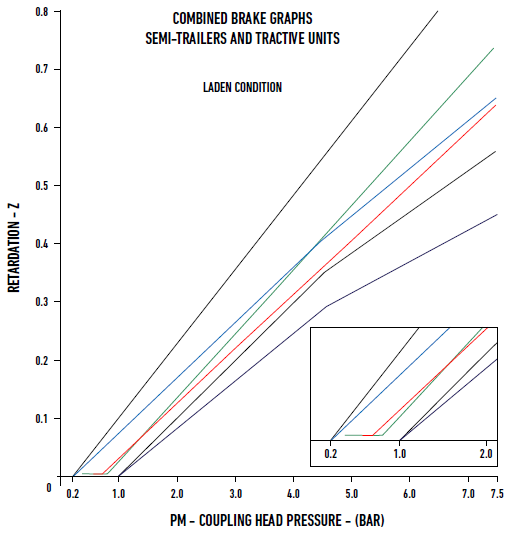

There is a similar graph for tractor units shown in Fig. 2. In this case the performance curve is shown as a green line in a black-bounded corridor. For tractor units, the brake performance at 6.5 bar ‘Pm’ must be a minimum of 50 per cent (0.50g).

If the brake balance between the tractor and trailer is equal, then the two braking curves would be coincident. Any disparity between the two curves means that either the tractor or trailer will be predominant when braking. A closer

inspection will show that the tractor and trailer curves are only coincident at a pressure setting of 1.5 bar ‘Pm.’ (Fig. 3). This situation is quite normal; 90 per cent of all brake applications occur at a pressure of less than 2 bar ‘Pm.’

By achieving coincidence or compatibility in this region of the graph, then we will have taken a huge step in fulfilling a tractor/trailer combination which has balanced braking.

EBS systems

The first thing to check is that the parameter settings agree with the calculation for that semi-trailer. BPW Limited engineers will be able to advise if the parameters are normal for the type of vehicle and operation under investigation.

Dynamic testing

In some cases, you may have to resort to dynamic testing. BPW has a dynamic testing procedure using laden heated runs and subsequent temperature checks to establish tractor and trailer compatibility and advise on potential adjustments.

EBPMS

An alternative approach to assessing brake performance is an Electronic Brake Performance Monitoring System (EBPMS). Supported by the DVSA, EBPMS can monitor in-service braking performance and provide a report that can be presented during a safety inspection and used instead of additional roller brake testing.

Having EBPMS allows operators to substitute a roller brake test between MOT tests by continuously monitoring braking events against the driver’s braking demand.

This also provides reassurance of brake performance without the need to take earning trailers off the road.

Using EBPMS also benefits from real-world data collected while the trailer is in use. This process gives more representative service brake performance values compared to RBT (laden and unladen) because it continuously monitors brake performance in real time.

EBPMS accesses data from the telematics system using real-world brake application, laden as used at normal working temperatures. All of this is presented to operators in straightforward viewable reports. These reports can be asset-based for individual trailers or fleet overview reports. The BPW EBPM systems can also communicate trailer fault codes and brake lining wear sensing information too.

Sharing this EBPMS data demonstrates compliance with current DVSA requirements (as set out in the DVSA Guide to Maintaining Roadworthiness) and can help reduce the number of roller brake tests from at least four to one per year, while automated error alerts enable proactive repair and maintenance scheduling.

The reliability of trailer braking systems is a non-negotiable aspect of road safety. As an industry leader committed to innovation and tailored solutions, BPW stands at the forefront, ensuring that trailers on BPW running gear navigate the roads with confidence.