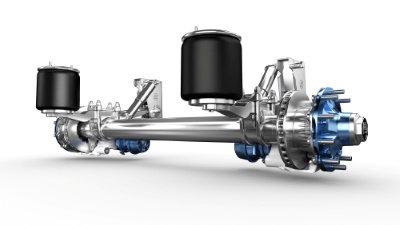

BPW puts suspension systems in the spotlight

BPW has outlined the details of its suspension systems offering, which it says can help maximise vehicle uptime without compromising safety or durability.

“High performance, low maintenance and reduced whole-life costs are at the heart of BPW suspension systems, making them a leading choice for fleet operators who demand reliability and efficiency,” said the firm.

“BPW offers a diverse range of air suspension systems tailored to meet the demands of various transport applications. Whether it’s long-haul efficiency or heavy-duty operations, BPW provides the right solution to ensure trailers operate at peak performance while minimising maintenance costs.”

For 9-tonne axles, BPW offers three types of suspension systems.

“The latest Airlight II Round (AL II-R), an advancement of the proven Airlight II (AL-II), features a conventional sprung steel trailing arm that delivers reliable trailer performance. The Eco Air, with its cast trailing arm design, offers the same physical properties as the Airlight II while accommodating different types of trailer designs and operating conditions.

“For more demanding applications, the Airlight Heavy Duty (AL-HD) incorporates reinforced components to withstand higher stresses and tougher conditions. For even greater load requirements, the SL suspension is available, capable of supporting loads of up to 14 tonnes.

“These solutions ensure maximum strength, stability, and efficiency across various operational applications.”

The Airlight II Round (AL II-R) suspension is one of the lightest axle and suspension systems on the market, says BPW, delivering outstanding performance and reliability for trailers with axle loads up to 9 tonnes.

“Its modular design incorporates a round-axle beam manufactured through state-of-the-art laser processing technology, enhancing stability while significantly reducing overall weight.

“The structural design of the trailing arms, hanger brackets and axle clamping arrangement can reduce the weight of a tri-axle trailer by up to 93kg, making it a highly efficient solution. This reduction in unladen weight contributes to lower fuel consumption and increased payload capacity, driving higher efficiency and greater revenue potential for operators.

“The suspension’s modular design allows for easy, low-cost replacement of individual parts and components, reducing repair costs by only needing to replace damaged or worn-out parts. The Airlight II Round also features flexible trailing arm technology, which can be precisely adapted to a particular vehicle and its application.

“The sprung steel trailing arm absorbs the strongest vibrations from the running gear and uneven road surfaces, reducing stress on the tyres, frame, vehicle body and the load itself, which extends the lifespan of the trailer.”

BPW LightTube

Building on the lightweight efficiency of the AL II-R, the BPW LightTube is the lightest 9-tonne chassis solution on the market, says the company, with a total module weight of less than 370kg.

“Designed for Airlight II running gear, this high-strength, hollow-section leaf spring connects the chassis and axle in a strong yet lightweight configuration.

“The result is increased payload capacity, reduced fuel consumption, and lower CO2 emissions, driving both environmental and operational savings and long-term sustainability. Its clamped spring seat arrangement also prevents cracking risks often associated with welded alternatives, ensuring long service life with reduced maintenance.

“By combining lightweight design with outstanding performance and reliability, the LightTube reinforces BPW’s commitment to delivering suspension systems that meet the highest standard in efficiency, reliability and durability.”

BPW describes Eco Air as a robust and modular air suspension system engineered for versatility across multiple road conditions.

“Its two-part cast trailing arm, combined with BPW’s precision-engineered steel rubber bush, ensures long-term durability and ease of maintenance. Unlike welded alternatives, the BPW Eco Air’s modular design allows for the quick replacement of individual components, reducing downtime and lowering repair costs.

“A key feature of Eco Air is BPW’s patented high-tech laser production process, which combines its typical clamped modular air suspension mounting with round-axle beams.

“Integrating the three-dimensional laser profile, etched on the bottom of the casting interface, creates a positive location with less clamping force. This technology ensures a secure fit with minimal clamping force, improving overall durability and stability.

“The specially designed asymmetrical steel rubber bush enhances load absorption and vertical track guidance while reducing tyre wear and improving ride comfort. With its optimised design and long service life, Eco Air provides a cost-effective solution for fleet operators seeking adaptable and efficient air suspension technology.”

For transport operations requiring higher load capacity, the Airlight Heavy Duty (AL-HD) suspension system is engineered for axle loads up to 12 tonnes.

“With reinforced components including thicker springs, welded spring seats, and robust M24 U-bolts, the AL-HD delivers superior strength and stability in the most demanding conditions,” said BPW.

“This system also features clamped connections, allowing individual components to be replaced as needed without requiring complete axle replacements. By minimising maintenance time and costs, the AL-HD ensures continuous fleet productivity while providing the durability required for demanding applications such as heavy haulage, construction logistics, and logging.”

SL Suspension

Designed for some of the heaviest loads and extreme conditions, the SL suspension system supports axle loads of up to 14 tonnes.

“Engineered for maximum robustness, it incorporates a low-maintenance U-bolt clamping arrangement, enabling easy replacement of components, when necessary, to minimise operational downtime.

“With a 100mm wide spring steel trailing arm, available in both single and twin-leaf configurations, the BPW SL suspension provides maximum durability for off-road and specialised transport applications.

“The combination of the axle body, axle connection, and trailing arm integrated with the air suspension support, forms a particularly robust unit capable of withstanding the toughest loads while maintaining stability and performance.”

The firm concluded: “BPW suspension systems offer fleet operators the flexibility to choose the right solution for their specific transport needs. Whether prioritising lightweight efficiency, modular maintenance, or heavy-duty strength, BPW delivers market-leading technology that reduces whole-life costs and maximises vehicle lifetime…

“With a proven track record of excellence, BPW suspension systems stand as the smart choice for operators seeking to maximise efficiency, durability, and value in their fleets.”