Clutch care tips from Diesel Technic

Drawing on the expertise of its UK Parts Specialists, Diesel Technic has provided some practical tips to help transport professionals improve clutch reliability and reduce costly rework.

Drawing on the expertise of its UK Parts Specialists, Diesel Technic has provided some practical tips to help transport professionals improve clutch reliability and reduce costly rework.

“Clutch problems are a frequent cause of commercial vehicle downtime—but many issues can be avoided with the right installation practices and checks,” said Lee Harris of Diesel Technic.

1. Watch for early signs of wear

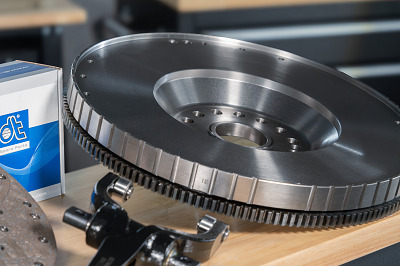

“Key components like the clutch disc, pressure plate, and flywheel work in sync to transmit power during gear changes,” said Lee.

“Look for:

- Embedded or worn torsional dampers

- Distorted contact patterns

- Blue discolouration on the flywheel (a sign of thermal overload)

“These symptoms indicate it’s time for closer inspection—or replacement.”

2. Never skip dimensional and torque checks

“If reusing a flywheel or bolts, always carry out dimensional checks against manufacturer specs,” he advised.

“Fasteners should be torqued precisely, and angle tightening followed where required. Overlooking this can lead to uneven load distribution and premature failure.”

3. Remove the clutch cover the right way

“During disassembly, release the clutch cover bolts in a crosswise sequence,” Lee added.

“This ensures spring pressure is relieved evenly and avoids warping of the cover or misalignment of contact surfaces.”

4. Align components carefully during reinstallation

4. Align components carefully during reinstallation

“Use centring sleeves when fitting the flywheel and a centring pin for the clutch disc. These help ensure accurate alignment – critical to preventing gearbox interference or poor engagement.

“Once aligned, apply torque to all bolts in a cross-pattern using the correct sequence and specifications.

5. Go easy on the grease

Over-lubrication is a common mistake, says Lee.

“Only apply grease if specifically instructed by the vehicle manufacturer. Excess grease can cause clutch drag or erratic function—leading to unnecessary performance issues.

6. Inspect the release mechanism closely

“Check for damaged components, wear, and grease contamination. Even minor issues in the release system can cause:

- Sluggish operation

- Inconsistent engagement

- Noise or vibration

“A quick inspection now could save a costly repair later.”

7. Don’t forget the diagnostics

“Modern clutch systems often require a parameter reset via diagnostic tools after replacement. Skipping this step can lead to ECU faults, incorrect engagement, or even drivability problems.”

Get it right first time

“Whether you’re running a haulage fleet, maintaining local authority vehicles, or servicing mixed-use assets, proper clutch installation and care can significantly reduce downtime and build long-term reliability,” Lee concluded.

Diesel Technic’s DT Spare Parts range includes over 900 clutch-related products – supported by experienced Parts Specialists across the UK.