Diagnostic expertise from Doctor Air Brake

Doctor Air Brake offers a range of diagnostic tools designed specifically for trailer brake systems, with the VTC Premium and Code Talk II forming the core of its current offering.

Doctor Air Brake offers a range of diagnostic tools designed specifically for trailer brake systems, with the VTC Premium and Code Talk II forming the core of its current offering.

The company says its range is built on the premise that trailer diagnostics should not require a tractor unit, but should be capable of powering and interrogating trailer systems independently.

“The VanTrailerCheck (VTC) Premium is, in essence, a tractor unit in a box. It provides 24-volt electrical supply and regulated air pressure to trailers, enabling testing of lighting circuits, ABS and EBS systems, CAN bus communications, and air brake circuits without coupling to a truck.

“Power comes either from a technician’s vehicle charge system or from mains supply units in their workshop available in 110V and 240V configurations which is then converted to 24V. The system connects via standard electrical leads for 24S, 24N & EBS and air brake lines, so no trailer modification is required.

“An optional wireless remote control allows brake actuation from a distance. This addresses a practical issue: assessing slack adjuster condition and brake wear traditionally requires one person in the cab applying the brakes while another inspects the running gear.

“The remote allows a single technician to handle both tasks, with the added capability of measuring chamber air pressures while positioned at the axles.”

The VTC Premium and the wireless remote together represent a small investment which will quickly improve efficiency and profits, says Doctor Air Brake.

“Code Talk II handles the electronic side. This handheld device reads and clears fault codes from trailer ECUs across the three major brake system manufacturers – Wabco, Haldex, and Knorr-Bremse – via a direct connection to the EBS diagnostic socket.

“The device displays real-time data of both live and stored electrical faults, also including air pressures, wheel speeds, system voltage, and ride height… Again with just a small investment you will be able to diagnose quickly and clear the faults once repairs have been completed.”

The company highlights the labour and asset efficiency gains its approach enables.

“Eliminating the need for a tractor during diagnostics frees that vehicle for revenue work. Removing the requirement for a second technician during brake inspections reduces labour allocation per trailer.

“For mobile service operations, the VTC Premium can be fitted to a support van, enabling diagnostic work at customer sites rather than requiring trailers to be brought back to base. Whether this capability justifies the investment depends on fleet size and operating model.

“Code Talk II’s value proposition rests on reducing dependence on external diagnostic services. Callout charges for dealer technicians typically run between £150 and £300 before any repair work begins. For operators with sufficient trailer numbers, bringing this capability in-house makes financial sense; for smaller fleets, the arithmetic is less clear-cut.”

There is also a preventative maintenance angle, Doctor Air Brake adds.

“Regular access to ECU data and real-time brake system information allows developing faults to be identified before they cause roadside failures. The cost difference between a scheduled workshop repair and an unplanned breakdown – with associated recovery charges, delay penalties, and customer impact – can be substantial.”

Its equipment covers all major brake system manufacturers in a single device, avoiding the need for multiple dongles or separate subscriptions.

Doctor Air Brake suggests most operators see payback within just a few months, though individual results will depend on fleet size, maintenance patterns, and current diagnostic arrangements.

“What is harder to quantify is the value of having diagnostic capability available when it is needed, rather than when an external technician can attend.

“In an industry where vehicle uptime directly affects profitability, that responsiveness may matter as much as the direct cost savings.”

The firms observes that, when discussing diagnostics, the conversation typically centres on fault-finding and maintenance scheduling.

The firms observes that, when discussing diagnostics, the conversation typically centres on fault-finding and maintenance scheduling.

“Yet the most significant diagnostic advances are now happening in real-time, with systems that continuously monitor the operating environment and intervene autonomously to prevent incidents before they occur.

“Doctor Air Brake’s ReverseSmart system exemplifies this evolution. The UK-manufactured radar auto-braking technology represents a step-change in how commercial vehicle operators approach both safety compliance and operational efficiency, particularly in challenging urban environments.”

It highlights one of ReverseSmart’s most valuable features: its integration capability with existing camera systems.

“Every auto-brake activation triggers recording, creating a comprehensive diagnostic log that captures exactly what happened and why the system intervened. This isn’t merely useful for post-incident analysis – it fundamentally changes how operators demonstrate due diligence.

“For fleet managers facing insurance claims or regulatory scrutiny, having timestamped evidence showing the vehicle systems worked exactly as intended provides invaluable protection.

“The data trail serves multiple purposes: validating driver behaviour, confirming system functionality, and providing the kind of documented evidence that satisfies both insurers and enforcement authorities.”

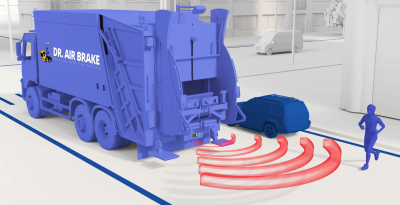

The environments where ReverseSmart is said to deliver its greatest value are precisely those where traditional safety measures struggle.

“Consider the operational realities facing drivers in tight urban spaces. Refuse collection crews working residential streets navigate a daily gauntlet of parked vehicles, pedestrians emerging from between cars, and children who may not understand the dangers posed by a reversing vehicle. Bin lorries operating in narrow alleyways face blind spots that no combination of mirrors can fully eliminate.

“Road sweepers present their own challenges. Drivers must simultaneously monitor the kerb line to ensure effective cleaning while remaining aware of cyclists, pedestrians, and other vehicles sharing the space. The cognitive load is substantial, and expecting perfect situational awareness during extended shifts is unrealistic.

“Road sweepers present their own challenges. Drivers must simultaneously monitor the kerb line to ensure effective cleaning while remaining aware of cyclists, pedestrians, and other vehicles sharing the space. The cognitive load is substantial, and expecting perfect situational awareness during extended shifts is unrealistic.

“ReverseSmart’s 77GHz radar sensor technology addresses these scenarios with programmable detection zones tailored to specific vehicle configurations. The system can be configured for detection width, height, and beam length, with adjustable speed-increment braking that brings vehicles to controlled stops appropriate to the circumstances.”

Given the proven effectiveness of radar auto-braking technology and the regulatory environment emphasising reasonably practicable safety measures, the case for wider adoption across municipal and commercial fleets is compelling, says Doctor Air Brake.

“Operators running vehicles in environments where vulnerable road users are present – refuse collection, street cleaning, urban delivery – should consider whether failing to deploy available safety technology remains a defensible position.”