Roadlink brings spring benefits with Weweler range

Components provider Roadlink International is an official distributor of Weweler road springs for the commercial vehicle aftermarket.

Components provider Roadlink International is an official distributor of Weweler road springs for the commercial vehicle aftermarket.

“To the naked eye, most leaf springs look more or less the same. It is only when you study the materials from which they are made and the production process used in their manufacture, that the difference becomes apparent,” said the company.

“Weweler leaf springs are redesigned to suit specific vehicle models and specific operational areas. This means that even if another spring looks the same, there is a risk that it will offer poorer comfort, payload, drivability and last but not least: lifetime.

“The high quality and long service life of Weweler springs assures comfort and road holding needed for safe and economical transportation work in an environment friendly way.

“Weweler’s modern process starts during the concept phase, which involves simulations, fatigue analysis and life-span calculations. All the steps in the process are targeted at realising optimum reliability and achieving a product that will deliver maximum efficiency rather than offering the cheapest springs on the market.”

Thanks to strict dimensional precision as per OE specification, Weweler springs are quick to install, says Roadlink.

“In addition, the springs are equipped with high quality silent blocs and accessories. VDL Weweler-Colaert has conceived a new type of silent bloc, which by its geometry assures comfort an improved road holding. The concept of the insertion into the eye, guarantees a better repartition of the traction and the torsion forces on to the main leaf, which improves the endurance and the performance.

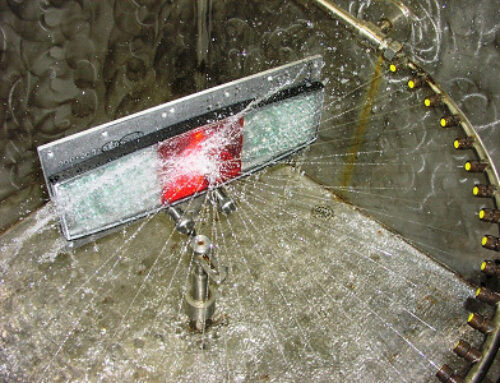

“Water-based paint is applied with special paint spray guns and is used as a standard for all parabolic springs and trailing arms. The anti-corrosive properties are even better than most zinc-based coatings.

“VDL Weweler-Colaert also exchanges technological knowledge and experience with some of the major technology institutes. Thanks to the partnership between Weweler, the research center WTCM and the steel manufacturers, it has been able to develop new process parameters. The use of new alloys in high-quality steel, a ‘Free Bending Hardening’ method (FBH) combined with high stress shot peening brought our products to one of the highest levels of endurance.”

“VDL Weweler-Colaert also exchanges technological knowledge and experience with some of the major technology institutes. Thanks to the partnership between Weweler, the research center WTCM and the steel manufacturers, it has been able to develop new process parameters. The use of new alloys in high-quality steel, a ‘Free Bending Hardening’ method (FBH) combined with high stress shot peening brought our products to one of the highest levels of endurance.”

Roadlink has all popular references held in stock, with all the required U-Bolts and fittings, at its central distribution centre, and has access to the entire range. The products feature a two-year warranty, and technical assistance can be provided.

Next-day delivery options are available and a VOR service if required. An online cross reference tool has 70,000 cross references loaded.