Driving the future: Cummins on the future of combustion

Engine specialist Cummins has offered its perspective on how its technologies can help tackle the dual challenges of reducing carbon dioxide (CO₂) emissions in line with European legislation for heavy duty vehicles (HDVs), and cutting tailpipe pollutants to forthcoming Euro 7 standards.

Engine specialist Cummins has offered its perspective on how its technologies can help tackle the dual challenges of reducing carbon dioxide (CO₂) emissions in line with European legislation for heavy duty vehicles (HDVs), and cutting tailpipe pollutants to forthcoming Euro 7 standards.

“Commercial vehicle operators and original equipment manufacturers (OEMs) are looking for future ready power solutions that balance performance with emission reductions,” said Bill Lamb, director, Engine Business Platform Strategy, Cummins Inc (pictured, right).

“Various zero and low-emission solutions exist for the on-highway industry, but heavy-duty applications such as intercity coaches and long-haul commercial vehicles are challenged by the amount of on-vehicle energy storage needed to fulfil current operations.

“In addition, there are also varying degrees of electric charging or hydrogen fuelling infrastructure available throughout Europe to support the use of these options, right now.

“Given the challenges for heavier duty applications, advanced internal combustion engine technology remains the most viable solution for many OEMs, offering a practical path forward until the necessary infrastructure is in place to support zero-emissions technologies.”

Bill Lamb described some of the benefits of advanced internal combustion.

“Cummins continues to view combustion as an essential part of the journey to lower tailpipe emissions,” he said.

“Diesel remains an important power source for many heavy-duty applications, especially long haul trucking or in regions that lack infrastructure.

“The X10 engine, part of Cummins’ Helm range, is designed to deliver significant emissions savings while improving performance and maintaining reliability.

“Using aftertreatment designed to comply with Euro 7 regulations, the compact and lightweight X10 offers a power range of 257 – 338 kW (345 – 453 hp), and achieves the new lower standards for NOx, particulates, hydrocarbons and N2O (nitrous oxide).”

He detailed several of the solutions that could assist fleets in achieving carbon reductions.

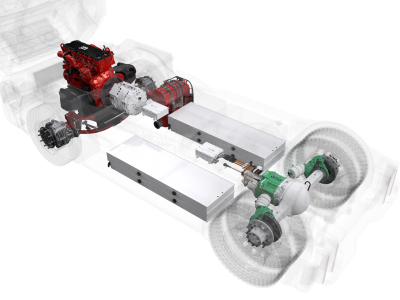

“As the push towards zero-emissions vehicles grows, hybrid powertrains may be a practical step to reduce emissions further, while providing flexibility in areas where infrastructure is underdeveloped,” said Bill.

“Strong, plug-in hybrid solutions can improve fuel efficiency by up to 30 per cent, reducing carbon emissions while providing operational flexibility for fleet owners.

“Future emissions reductions can be enhanced with renewable fuels such as hydrotreated vegetable oil (HVO) and renewable natural gas. HVO significantly reduces lifecycle CO2 emissions by around 90 per cent well-to-wheels and is a ‘drop-in’ solution available today.”

Bill emphasises the advantages of the fuel agnostic technology that the company has been developing.

“Cummins continues to invest significantly in developing its internal combustion engines and in 2024 launched its Helm fuel agnostic platforms,” he said.

“These engines operate on advanced diesel, renewable natural gas or zero-carbon hydrogen. Their common base provides integration simplicity for OEMs, and gives fleet owners the flexibility to choose products that match their business and sustainability goals, alongside the familiarity of combustion technology.

“Each engine within the Helm range operates on a single fuel, but base elements are shared across multiple variants. Design changes are made largely above the head gasket to enable specific capabilities for different fuels.”

Hydrogen engines in the Helm range present a promising solution that leverages existing internal combustion engine technology, he says, while reducing vehicle redesign and installation costs for OEMs.

“This approach provides a pathway to decarbonisation without a complete shift to fuel cell or battery electric systems. Using green, zero-carbon hydrogen as a clean fuel significantly reduces emissions while preserving the performance, durability and refuelling convenience of traditional internal combustion engines.”

With the necessary reduction targets for the transport industry in place, the role of manufacturers like Cummins will continue to evolve, Bill contends.

“The company has invested heavily in R&D, acquisitions and partnerships to broaden its product portfolio, which now includes engines and related components, brakes, axles, e-axles and zero-emissions power technologies through the Accelera by Cummins brand,” he explained.

“Successfully decarbonising the commercial vehicles sector will require a mix of all power technologies including advanced internal combustion engines running on renewable fuels, hybrid powertrains, battery electric and fuel cell technologies.

“By leveraging its comprehensive approach, Cummins is supporting the journey to a more sustainable future while meeting the varied needs of heavy-duty applications.”