HVS details modular hydrogen platform

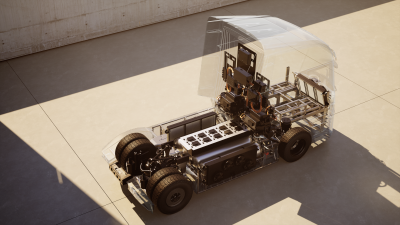

Scottish hydrogen truck developer HVS, which launched its fuel-cell tractor unit at this year’s Commercial Vehicle Show, has unveiled details of its modular platform, which it says will offer truck operators maximum flexibility from a single base vehicle.

Scottish hydrogen truck developer HVS, which launched its fuel-cell tractor unit at this year’s Commercial Vehicle Show, has unveiled details of its modular platform, which it says will offer truck operators maximum flexibility from a single base vehicle.

The company’s tractor unit will be available with two different types of e-axle – one medium power and one high power – and with up to three hydrogen tanks, depending on the customer’s range requirements. In addition, the hydrogen fuel cell powertrain can be specified with two different power outputs depending on the customer’s payload and mission requirements.

The modular platform is built on a fixed wheelbase, which means the vehicle’s footprint does not change, irrespective of specification.

HVS says the vehicles have been specifically developed to maximise driver comfort while the platform is purpose built around the hydrogen powertrain. The design includes a suspended cab at the front and a fixed tower at the rear, housing the thermal and powertrain systems.

This platform format breaks with the industry-standard tradition of variable cab types and sizes – such as big, medium and small, and high/low-roof – and means that even the smallest variants have the same spacious cab as the largest models, says the company.

Pete Clarke, head of design at HVS, said: “We’re offering maximum modularity within a single base vehicle platform, and we would never have been able to achieve this level of flexibility and optimisation with a diesel-powertrain derived vehicle design.

“Our vehicles have been created for a fundamentally different technology within an all-new package, so every cubic millimetre has been designed afresh. We initially calculated the maximum wheelbase possible to achieve the required turning circle and manoeuvrability for the target market.

“The design process then began with the optimal powertrain format, around which the vehicle design was then created – ensuring that form followed function.

“Rather than playing with a configurator, HVS can put the best value package together for customers based on information about what they do, the loads they will carry, along with their ranges and routes.”

The modular platform allows operators to define their HGV specification relative to their operation, says the firm, while simultaneously transitioning to a zero-emission fleet. HVS’ approach is to ensure that it supplies vehicles in the most appropriate form for the job requirement.

The modular platform’s flexibility is such that the trucks can easily be retrofitted with alternative modules such as additional hydrogen tanks if the fleet’s duties change or expand.

This has the effect of minimising the total cost of ownership (TCO) and provides a compelling business case for early switching to CO2-free vehicles, claims HVS. The company’s emphasis is on price-per-mile usage and ensuring operators achieve the performance, range and durability they require.

Vehicle platform longevity and recycling of the electrochemical modules are further benefits of HVS’ modular platform, the firm adds. Its adaptable architecture means core electrochemical modules, including the battery and fuel cell, can be swapped out for more advanced equivalents as the technology advances.

This future-proofs the vehicle and vastly increases its potential operational life, contends HVS, while other less critical components, such as interior trim or body panels, can also be simultaneously refurbished when a drivetrain upgrade is performed.

HVS is developing new hydrogen drivetrains for its future vehicles, with a focus on delivering maximum power and range for each operational duty class. With this modular platform its 4×2 tractor unit is said to provide a zero-emission range of up to 370 miles/600 kilometres.