Autolift: the pit jack professionals

Autolift Ltd specialises in the design and manufacture of commercial vehicle pit jacks, jacking systems and jacking beams, and the supply of a range of pneumatic heavy duty hydraulic jacks.

Autolift Ltd specialises in the design and manufacture of commercial vehicle pit jacks, jacking systems and jacking beams, and the supply of a range of pneumatic heavy duty hydraulic jacks.

The company says its equipment is ideally suited for workshops maintaining HGV and PSV vehicles. All its goods are manufactured in the UK.

“We have over two decades’ experience of designing and manufacturing reliable HGV vehicle pit jacks, from 13 and 20-tonne models to a large 40-tonne model,” said Autolift.

Customers can opt for either a manual or air-assisted product.

“All our pit and garage equipment is robust, safe and reliable, providing a comprehensive solution to all vehicle lift and pit jack requirements,” the firm added.

The 13T and 20T capacity air-powered jacks provide a lifting stroke of 400mm. A purpose-designed high output air pump provides the power to two lifting cylinders. To improve safe working, hydraulic locking is provided by 90 degrees isolation valves, which are locked when the desired lifting height is reached. They also provide easy visual confirmation that the jack is locked off and allow each cylinder to be operated independently.

Operation is simple, efficient and safe, says Autolift; the user raises the air valve lever to quickly advance the lifting cylinders to the load, and then the air pump automatically takes over to lift the load.

When the desired height is reached, the user closes the cylinder isolation valves. To lower the load, they can open the isolation valves and release the dead man valve on the pump. When the load is off the cylinders, the user can hold down the air valve lever to quickly retract the cylinders.

Covering pit widths from 750mm – 1,500 mm, the beams move on four wheels, which have needle roller bearings to ensure ease of movement up and down the length of the pit. Parallel wheels are fitted as standard to suit flat angle pit edges with tapered wheels as an alternative for use on RSJ supporting rails. Spring loaded wheels can also be provided; these retract when the jack is under load, locking its position.

Further advantages highlighted by Autolift include chrome plated rods and the latest seal technology, said to ensure a long and trouble-free life. The product is covered by a five-year warranty. Each unit is fully tested, marked with a serial number and supplied with a test certificate.

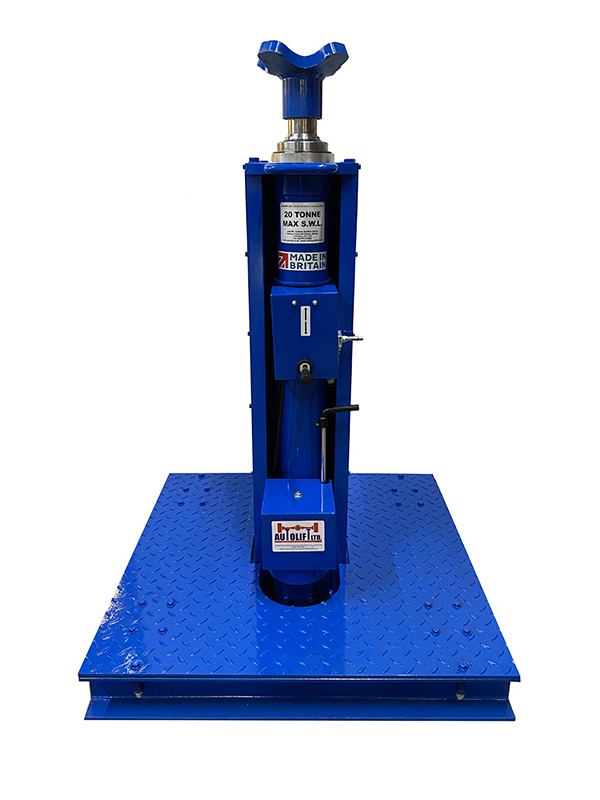

Further items in the range include 15T and 20T capacity floor jacks, which are used on the pit floor instead of a conventional jacking beam running on pit edge rails – with a lifting stroke of 750mm, minimum height of 1,200mm and maximum height of 2,000mm.

Further items in the range include 15T and 20T capacity floor jacks, which are used on the pit floor instead of a conventional jacking beam running on pit edge rails – with a lifting stroke of 750mm, minimum height of 1,200mm and maximum height of 2,000mm.

The lifting cylinder is mounted in an 800 mm square sprung base and is easily moved on four castors. On loads above 600 kg the castors retract and the unit sits solidly on the floor.

Also available is a 1.5 tonne transmission jack, designed and manufactured for use in a pit or under a four-post lift, for use when removing and installing engines and gearboxes.

The jacks are designed and manufactured for long lasting reliability and ease of use, says Autolift. A foot pedal-operated hydraulic pump is said to allow effortless lifting and hands-free operation. Precision engineered valves enable controlled lowering, the company adds, while high quality castor wheels and side handles allow the units to be easily moved.