Steertrak offers wheel alignment advice

On-site service specialist Steertrak has warned of the extent of the impact on fuel consumption, tyre wear and CO2 emissions if wheels are misaligned, as well as the potential consequences for driver comfort and safety.

On-site service specialist Steertrak has warned of the extent of the impact on fuel consumption, tyre wear and CO2 emissions if wheels are misaligned, as well as the potential consequences for driver comfort and safety.

“It is understood that at a constant 56 mph around one third of a vehicle’s energy and fuel is used to overcome the rolling resistance of the tyres, and this is primarily affected by tyre selection, tyre pressure and wheel alignment,” said the company.

“Correcting even the smallest levels of misalignment will reduce this rolling resistance and can have a significant effect on fuel and tyre economy. In terms of numbers, industry research and Steertrak customer data suggest savings of typically up to five per cent on fuel and over 20 per cent on tyres can be readily achieved.

“In instances of poor alignment this figure can be much higher. And whilst historically savings from such services may have been somewhat overlooked by some operators, unprecedented escalation in fuel prices, tyres and thin margins and low cost of alignment services are increasingly making wheel alignment maintenance an attractive easy financial win.”

Steertrak refers to research by Volvo and Michelin which showed that two thirds of the trucks on European roads are out of alignment.

“Every time a vehicle mounts a kerb, hits a pothole, or runs along the verge change there is a chance that the wheel alignment may be affected,” the company continued.

“Repeated knocks over time will undoubtedly mean the alignment will need to be reset: however, more frequently it is down to maintenance. When rolling chassis parts are changed, often vehicles simply don’t get set up straight afterwards.

“With the increase in internet shopping and urban home delivery, the numbers and severity of misalignment of these vehicles is likely to be greater.”

There is much misunderstanding around the difference between basic tracking and commercial vehicle alignment, contends Steertrak.

“Often tracking of cars and some vans is thought of as setting the front (and sometimes the rear) wheels parallel to each other.

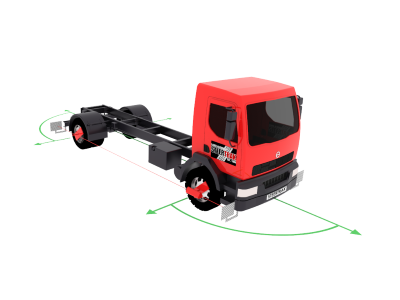

“The requirement for trucks and trailers is different. Here it is necessary to be able to set each individual wheel parallel to the vehicle so the reference point needs to be the chassis itself.

“The requirement for trucks and trailers is different. Here it is necessary to be able to set each individual wheel parallel to the vehicle so the reference point needs to be the chassis itself.

“There is a common misconception that you cannot align fixed axles such as trailer or drive axles. Although the tracking on these axles cannot be set, inter axle adjustment and adjusting the wheels parallel to the chassis can be made. Additionally. considerations need to be made for the steering box timing.”

The three main pillars of good wheel alignment are the right equipment, the right technician and the right knowledge, says Steertrak.

“The equipment must be accurate and able to reference the centre line of the chassis, and all measurements have to relate back to this centre point. The best equipment, such as used by Steertrak, allows the technician to perform what is called “run- out compensation”, which means it can find the true running centre of the axle stub to make the vital measurements.

“Finally, the equipment has to be capable of measuring all axles including the front steered axle, second steer, lift and drive axles, and trailer axles.”

The wheel alignment process cannot be separated from the general operation and maintenance of a vehicle, adds the firm.

“A customer might think they have a wheel alignment problem, but the underlying problem may be mechanical – such as seized or worn king-pins, a bent track bar, worn joints or incorrect steering pump pressures.

“To be able to get to the root cause of the problem, the technician performing the wheel alignment needs to be able to think beyond what the wheel alignment equipment is telling them.”

The company also explained that vehicle manufacturer specifications often have quite broad tolerances within the specifications they set. This is because, when they assemble vehicles, they cannot envisage all possible end user scenarios.

“They don’t see what final equipment or load space is fitted onto the vehicles, and they don’t know anything about the final loads that are being carried and the terrain being driven on.

“A vehicle may set within the manufacturer’s tolerance range, but that does not necessarily mean that it has been optimised for a specific end user.

“To get the best value out of wheel alignment, it is necessary to set a vehicle up according to how it is being used. That is where the speciality knowledge and skills of companies like Steertrak can really make a difference.”

While some operators wait until they see major tyre wear before getting the wheel alignment checked, at this point the damage is done, the company contends, and money is already down the drain.

While some operators wait until they see major tyre wear before getting the wheel alignment checked, at this point the damage is done, the company contends, and money is already down the drain.

“And it is not just the cost of replacing the tyres, as for every pound wasted on tyre wear around several pounds would have been wasted on fuel.

“Many fleet engineers now insist on a wheel alignment check as part of the vehicle’s annual MOT, as well as every time a steering or suspension component is replaced.”

Established in 1984, Steertrak’s independent fleet of commercial vehicle mobile wheel alignment engineers has a national presence, and specialises in trucks, trailers, PSVs, vans and cranes.

“Our dedicated engineers can come to your site and are able to optimise all aspects of your vehicles steering and running gear to improve fuel economy and reduce tyre wear. We provide detailed reports on every vehicle.”

To learn more or for an analysis of potential fleet savings, readers can contact Steertrak via the website.