VBG enhances coupling systems portfolio

VBG, which has more than 70 years’ experience in the development of coupling technology, says its latest- generation products may look familiar on the outside, but are completely new on the inside.

VBG, which has more than 70 years’ experience in the development of coupling technology, says its latest- generation products may look familiar on the outside, but are completely new on the inside.

“The new generation of VBG couplings is a major leap in innovation in the industrial segment in which VBG operates,” said the firm.

“The combination of refined mechanics and new digital technology further increases safety and reliability, while also opening doors for functions that will be offered in the near future.

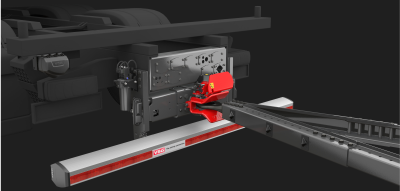

“Among other things, the mechanical improvements have resulted in more compact coupling dimensions. The power actuator, manual handle and VBG’s valve box have also been made smaller and more lightweight which creates better options for different types of installation on trucks. The products are now also easier to maintain, which saves time and extends the service life.”

VBG says it will continue to serve existing products on the market by enabling upgrades to the new generation of technology. In this way, new functions can be added to today’s couplings, which extends the product life cycle and adds value to customers’ investments.

“VBG aims to make everyday life in the road transport industry safer and simpler,” added the company.

“To accomplish this, a completely new CAN bus-based electrical infrastructure has been developed which, together with digital sensors, will facilitate functional growth in the future. This offers great development potential for the future and serves as the first step towards digitised functions which will help drivers to handle coupling functions sustainably. Extensive road tests have already proved to be extremely successful.”

VBG is also a leading provider of underrun protection systems which, in the event of a rear-end collision, prevents smaller vehicles from becoming lodged underneath the truck or trailer.

“For the purpose of increased safety, it is an important and integrated part of VBG’s coupling solutions,” said the company.

“VBG’s new series of modular underrun protection can be installed quickly and easily. The systems are designed to occupy the smallest possible area on a vehicle chassis and have a surface finishing of the highest class. Thanks to a wide range of endplates, arms, and protective beams, the systems can be adapted to any vehicle from popular manufacturers. All systems and components are tested and certified in accordance with UNECE R58 Revision 3.”

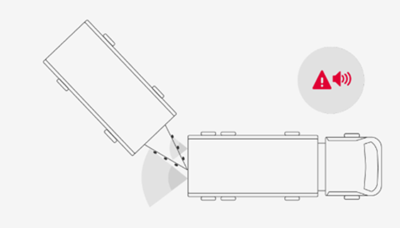

The company’s portfolio also includes a system that can warn drivers of jackknifing, whilst also providing the opportunity for safe coupling through sensor-based guidance.

The company’s portfolio also includes a system that can warn drivers of jackknifing, whilst also providing the opportunity for safe coupling through sensor-based guidance.

VBG Driver Assist alerts the driver when reversing via audio signals from within the cab, when the system detects that the vehicle is at risk of jackknifing. The audio signals start at a 40-degree angle and end with a constant tone when the maximum warning angle is reached.

“The guidance function when connecting means that the driver is provided with guidance in the truck via voice control to reach the correct position,” said the firm.

“When the vehicle is reversed and approaches the drawbar, the system notifies the user via the speaker that the guidance is active, which occurs at a distance of two metres from the coupling. A voice then provides information as the driver reverses on what corrections are required to the truck in order to manoeuvre into the correct position for coupling.

“The system increases levels of safety for drivers and other road users, while minimising the risk of costly damage to the vehicle. The system works for trailers, centre axle trailers and dollies.”