Forvia Hella: spend wisely on lighting

As operators grapple with escalating costs, components manufacturer Forvia Hella has highlighted the importance of wise expenditure in vehicle maintenance, which it says cannot be overstated.

As operators grapple with escalating costs, components manufacturer Forvia Hella has highlighted the importance of wise expenditure in vehicle maintenance, which it says cannot be overstated.

“Beyond the initial price tag, durability and longevity are paramount considerations,” said Spencer Grinham, SOE sales director at Forvia Hella.

“The choice of parts extends far beyond mere economics – it’s a strategic investment in reliability and efficiency.”

Forvia Hella offers a range of vehicle lighting special original equipment (SOE), including for trailers. The range includes amber lighting, work lights, beacons, strobes and light bars; and the company says its stringent processes mean operators will only be fitting Forvia Hella SOE parts once, thereby saving in the long term.

Forvia Hella SOE recently exhibited at the Commercial Vehicle (CV) Show, which took place from 23-25 April at the NEC in Birmingham. A team of experts were on-hand at the company’s 44m² stand to advise how Forvia Hella can address the specific challenges and requirements of individual operators. Innovations displayed included new work lights and scene lights made using a rust-proof composite material.

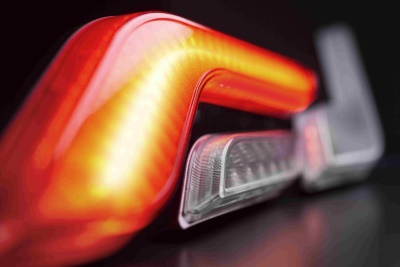

Hella’s Shapeline lamps generated strong interest, the company reports. The new modular concept facilitates various shapes and styles across a wide selection of single and multi-function lamps. Depending on lighting function requirements, Shapeline lamps are available with yellow, red or white cover lenses.

New products on the stand included Hella’s K-LED Rebelution rotating beacon. Doing away with the traditional beacon dome, it benefits from a new minimalist design, says the firm, while a permanently visible warning signal is emitted with an even stronger circumferential signal, making it truly unique.

New products on the stand included Hella’s K-LED Rebelution rotating beacon. Doing away with the traditional beacon dome, it benefits from a new minimalist design, says the firm, while a permanently visible warning signal is emitted with an even stronger circumferential signal, making it truly unique.

“At the heart of our SOE offering lies a manufacturing philosophy, which we refer to as ‘the circle of life’,” said Spencer.

“One of the key differences between Forvia Hella SOE and other suppliers is that we are not a distributor. We are the manufacturer and the whole process takes place under our roof, ensuring unparalleled quality control.”

From conception to execution, every step is meticulously managed by Forvia Hella SOE in-house, says the company; an extensive team of engineers cover all aspects of design and feasibility before weeks, sometimes months, of prototype trials.

“Every prototype undergoes extensive testing, initially through computer simulations and later in the lab for physical tests,” added Spencer.

“Proven concepts are only approved following months of longevity assessment in our state-of-the-art labs.”

Tests include chassis vibration analysis and exposure to extreme temperatures inside climate change chambers, capable of going from -40°C to 80°C in just a few seconds.

Once proven to be ready for real-world use, Forvia Hella SOE oversees the entire production process, which it says enables it to maintain uncompromising quality.

Manufacturing plants are situated across the globe. From Europe to India to New Zealand, each facility adheres to exacting standards, ensuring consistency and reliability in every product.

“Our offering doesn’t end after the sale of a product,” said Spencer.

“We’re here to support industry through our custom solutions. Here in the UK, we have a dedicated team providing comprehensive sales support, quality assurance, customer service, and logistics.”