Jost adds value with axle and coupling technology

Commercial vehicle technology provider Jost reports that two of the key axle products within its portfolio – the new Drum Modular Axle series and CSA command steer axle – are garnering plenty of praise within the industry.

“Following the acquisition of Tridec and Mercedes-Benz Trailer Axle Systems, Jost as a company has wasted no time in becoming of Europe’s standout manufacturers for steering, suspension and axle systems for truck and trailer applications,” said John Meehan, sales manager – North, Scotland & Ireland at Jost GB.

“Standing out from the competition in what is already a congested market, one of Jost’s major offerings has been to cater for its customers; providing appropriate solutions for their fleet, whatever their requirements.”

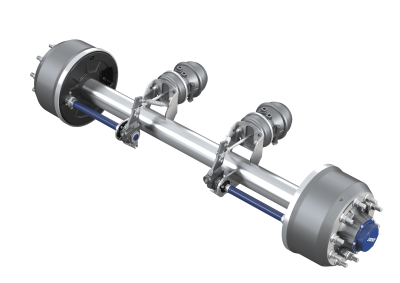

The Drum Modular Axle (DMA) series has expanded the Jost Axle portfolio in recent years, and this latest iteration is said to offer customers a technological solution they may not have had access to previously. Using a unique specification to meet the needs of the operator, the DMA has been specially designed to ensure easy maintenance and service – all of which is geared towards reducing downtime in the workshop.

The Drum Modular Axle (DMA) series has expanded the Jost Axle portfolio in recent years, and this latest iteration is said to offer customers a technological solution they may not have had access to previously. Using a unique specification to meet the needs of the operator, the DMA has been specially designed to ensure easy maintenance and service – all of which is geared towards reducing downtime in the workshop.

The axles utilise Durable Leaf Spring (DLS) technology to optimise adaptability across different chassis configurations, and are said to ensure flexibility for workshop technicians thanks to the implementation of a bespoke outboard drum design. In addition, brake shoes are fitted with an optimal cam roller. The cam roller controls the range of movement of the brake shoes and also the contact pressure, explains the company, which can be simply changed without the need for any additional specialist tools or equipment.

Another benefit of the DMA Series highlighted by Jost is the Self-Setting Automatic Slack Adjusters (S-ASA) that come as standard. The company ensures that the S-ASA is offered as a standard feature across all OEM axles, thus providing operators with solutions from the factory. It also provides optimal lining drum clearance.

One final feature that the S-ASA encompasses is an anchor bracket that can be fixed to any point within its arc of rotation, adds the firm, thereby eliminating what is usually a common in-service maintenance issue.

Jost also highlighted the benefits of its CSA command steer axle, which is for use in conjunction with an electronic steering system (EF-S), and is said to offer fleets a unique and tailored solution for the future generation of logistics.

Jost also highlighted the benefits of its CSA command steer axle, which is for use in conjunction with an electronic steering system (EF-S), and is said to offer fleets a unique and tailored solution for the future generation of logistics.

The axle is perfect for use in urban areas, rural country roads and hard-to-reach locations, says the company, and provides customers with a smaller steering radius and a low steering force, as well as compatibility across Jost’s extensive range of steering systems.

“Combining with the EF-S, the CSA can help long trailers reach the legal turning circle requirement, with a high manoeuvrability,” said John.

“This system helps to reduce business overheads in the shape of saving tyre wear and improving fuel efficiency – a perfect combination when it comes to convenience and efficiency.”

At a recent Driver Day event at Lymm Truckwash in Cheshire, meanwhile, Jost experts were on hand to demonstrate the company’s KKS Push Button automatic coupling system, which can safely connect all air and electrical connections without the need for the driver to climb onto the back of the cab, thus reducing the time taken to couple and uncouple a trailer, and helping to mitigate the risk of accidents.

The driver is able to coordinate the process, including the raising and lowering of the landing legs, via a dedicated remote control panel in the cab, incorporating real-time status reporting and sensor monitoring. A standard pneumatic ram ensures the effortless release of the fifth wheel even when the trailer is hitched.

The driver is able to coordinate the process, including the raising and lowering of the landing legs, via a dedicated remote control panel in the cab, incorporating real-time status reporting and sensor monitoring. A standard pneumatic ram ensures the effortless release of the fifth wheel even when the trailer is hitched.

The system is said to cut trailer changeover times up to 50 percent, by avoiding the need to manually wind landing legs up and down, connect lines, release the fifth wheel and climb onto the catwalk. Especially where short distances and frequent fifth wheel changes are involved, the system can also reduce costs significantly, says Jost, and is ideal for vehicles carrying cargo with significant safety or security requirements.

The latest development for the solution is the KKS-U Connector, which is retrofittable to existing trailers.

Fitted to the underside of the trailer, the KKS-U Connector is an alternative installation variant and enables fleet operators to equip existing trailers easily with the KKS. It connects all the mechanical, electric, and air connections between the truck and trailer, eliminating the need for the standard vulnerable air, electrics and ABS/EBS spiral lines.