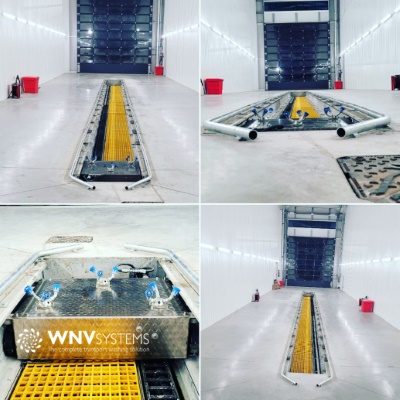

Under-chassis EV bus washing from WNV

WNV-Systems’ automatic under-chassis wash system offers multiple programmes to suit manufacturers’ chassis cleaning guidelines – such as BYD-Alexander Dennis E200MMC and E400MMC EV buses – all operating off an HMI touch screen panel.

WNV-Systems’ automatic under-chassis wash system offers multiple programmes to suit manufacturers’ chassis cleaning guidelines – such as BYD-Alexander Dennis E200MMC and E400MMC EV buses – all operating off an HMI touch screen panel.

WNV-Systems, which celebrates its 30th anniversary this year, designs, manufactures, supplies and installs heavy vehicle wash systems primarily for the bus, coach, HGV, local government and rail industries, including the patented automatic under-chassis wash system.

The system typically takes 20 minutes to clean a double-decker bus or refuse vehicle to full MOT standards, says the company, providing a full width clean from its nine high pressure rotating water jets.

Darren Bright, business development director at WNV-Systems, said: “The wash achieves this quality of clean and time efficiency even with extremely dirty vehicles, including those that are regularly driven over landfill sites or on salt gritted winter roads.

“The machine is robust and energy-efficient, built using low energy consumption waterproof sealless pumps, to deliver maximum life span, minimum maintenance and reliability.”

Under-chassis cleaning has historically been done by hand, which Darren says can have significant health and safety implications for cleaning staff. In addition to the cost and time-saving benefits of the WNV machine, there are very few health and safety concerns, the firm says, as no-one needs to be under the vehicle during the cleaning operation.

The under-chassis washes have been installed at the sites of several major bus operators including Go-Ahead Group, National Express, First Bus, Arriva and Stagecoach to name a few, as well as local authorities and councils across the UK and abroad.

WNV-Systems now also operates across America with its USA Automatic Undercarriage Wash System, via distributors across the country.

WNV-Systems now also operates across America with its USA Automatic Undercarriage Wash System, via distributors across the country.

The automated under-chassis wash is normally installed in tandem with a water reclamation system specifically designed by WNV-Systems to process the effluent produced in the cleaning operation. In doing so, it recycles up to 90 per cent of the water used to wash a vehicle, helping to save money and protect the environment.

This water reclamation system is fully approved by DEFRA (the Department for the Environment, Food and Rural Affairs) and meets all local water authority standards, says WNV.

The company estimates that the reclamation system can pay for itself in two/three years, depending on usage. The installations are eminently suitable for integration into rainwater harvesting systems, it adds; a number are already in operation providing significant savings in water costs.

If supplied with a reclaim and rainwater harvesting system, the wash can clean without any additional fresh water input being required at all.

Further products available include 3 Brush Rollover Top Wash, Drive Through Bus Wash, Static Cabinet pressure washes (Diesel & Electric), along with associated chemicals such as traffic film remover (TFR), shampoos and Biocide Puritan for the aid of bacteria and legionella control.

Readers can find more information, or arrange a free site survey, via the website.