Top tips for keeping vans cool

Delphi Technologies offers technical advice to help ensure LCV air conditioning is in prime condition

Delphi Technologies offers technical advice to help ensure LCV air conditioning is in prime condition

Keeping the air conditioning system in tip-top condition isn’t the obvious necessity when it comes to maintaining a hard-working LCV, but it’s fast-becoming part of a servicing schedule rather than an afterthought.

As LCVs become increasingly car-like in their driving experience, with manufacturers and customers placing greater emphasis on driver comfort and convenience, more and more LCVs now feature air conditioning as standard, rather than an option or simply not even available at all.

Simple lack of use impairs an air conditioning system, and while many LCVs are on the road more than off it – and, unlike many privately-owned cars, they haven’t been sidelined during the pandemic – colder weather and the effect that utilising the system can have on fuel economy means some drivers are reluctant to literally give it a blast.

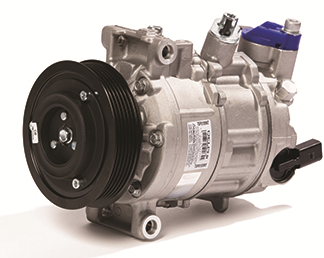

Firing up the air conditioning after sustained inactivity can be too much for the system’s compressor, while the systems of vans that have seen less activity than normal can smell bad – the easy-to-recognise smell of damp being a result of bacteria and mould that have built up in the system due to its lack of use.

For garages, air conditioning servicing on LCVs represents another possible revenue stream, but only if they have access to the correct parts, equipment, and knowledge.

“For many professional drivers, air conditioning servicing is something that’s not obvious, but it’s essential maintenance in order to optimise comfort, while a neglected system can even be detrimental to the health of a van’s occupants,” said Julian Goulding, Northern Europe marketing manager at Delphi Technologies Aftermarket.

“First and foremost our focus in on delivering high-quality, reliable product, giving technicians the right part to effect a quality repair that meets or exceeds OE standards for quality and durability.

“But we also complement this with comprehensive training that includes a two-day AC with F-Gas Certification course which covers the fundamentals of AC, detailed system/component operation, component servicing, climate control systems, hybrid system differences, recovery, charging, and recycling and leak detection methods, combined with an assessment for EC307/2008 F gas legislation.

“We also offer comprehensive support through our technical hotline and vehicle technical information software.”

For technicians completing AC servicing, Delphi Technologies has comprehensive advice and technical tips.

One of the most common causes of AC failure is a lack of lubrication. This can happen when there’s a refrigerant leak in the system from either a hose, o-ring, compressor, condenser, or evaporator. Whilst most vehicle manufacturers are now factory installing dye in their AC systems because access is much tighter in modern light commercial vehicles, detecting leaks can be tough.

AC failure can also happen if a newly installed compressor is not oil-balanced with the correct type and amount of lubricant, while another common cause of AC failure is air and moisture in the system.

To operate at its best, an AC system should contain less than two percent air by weight. For every one percent increase in the amount of air, there will be an equivalent reduction, approximately one percent, in cooling performance. More than six percent air can cause a noticeable decline in cooling performance, and worse still, potentially lead to the evaporator freezing-up.

While there’s no set period for maintenance products, it’s critical to service them regularly. Take the receiver drier as an example; when the system is exposed to the atmosphere it can become very quickly saturated from humidity in the air. If this occurs, the desiccant is no longer effective and will not provide future protection.

It should be replaced every time the system is opened and as a minimum every two years. Cabin filters can also become easily clogged, reducing the effectiveness of the filter, and in turn the performance of the heating and cooling system. To prevent this, filters should be changed  every 12 months, or six months if a vehicle is mainly used within urban areas – much like LCVs used for multi-drops are.

every 12 months, or six months if a vehicle is mainly used within urban areas – much like LCVs used for multi-drops are.

Goulding concluded: “This summer could see a significant rise in the demand for AC servicing, but the increased complexity of new vans with more integrated systems means it’s more critical to offer a complete solution; covering OE quality parts, diagnostic tools, OE-level training, technical support and best practice advice.

“Only garages with this specialist support can take advantage of the rise in vans fitted with air conditioning, making the potential profit gains even greater still.”