Totalkare wheel servicing range keeps fleets rolling

Workshop equipment specialist Totalkare offers an extensive portfolio of tyre and wheel servicing equipment, including recent additions to its wheel alignment and tyre changer offerings.

Workshop equipment specialist Totalkare offers an extensive portfolio of tyre and wheel servicing equipment, including recent additions to its wheel alignment and tyre changer offerings.

The company emphasises the benefits for workshops of all sizes of bringing tyre changing operations in-house, thereby enabling both financial and time savings without the need to outsource. Its tyre changer portfolio, which was expanded last year, covers both heavy-duty and light commercial vehicles. The offering ranges from entry-level machines through to fully automatic setups.

“As workshops see the costs of maintenance and repair for dated machinery continue to rise, investment in the latest and safest equipment ensures they are able to provide continuous service,” said Totalkare.

“This increased business efficiency is key to ensure preparation for any job that might roll through the workshop doors, and Totalkare are continuing to monitor the marketplace and expand their offering to best support the hard workers in this core industry.”

The product range includes NAV101, a commercial tyre changer capable of dismounting and mounting a tyre in only 30 seconds thanks to its unique design featuring adjustable arm positioning, a four-roller system and bead breakers supported by two separately controlled arms.

Meanwhile the NAV11 heavy duty truck tyre changer provides the ability to service a wide range of wheels, including super-single, thanks to the operating dimensions of the clamping unit and head-tool carriage.

Light commercial units include the HP641, an automatic tyre changer with double-acting bead breaker cylinder which is designed to work on even low-profile and large-sized steel or alloy rims; and the HP643 designed for high output garages, working on any wheel up to a maximum width of 15”, which features an extra-wide, heavy-duty frame.

Totalkare also recently announced a UK distribution arrangement with Hunter Engineering Company, the wheel alignment and balancing technology manufacturer. Hunter’s Heavy Duty Wheel Alignment system incorporates precise sensors and software to enable accurate measurement and adjustment of wheel alignment parameters, says the company, thereby significantly enhancing vehicle safety, tyre longevity, and fuel efficiency, while minimising downtime and repairs.

Meanwhile, the Hunter range also includes Heavy-Duty Quick Check, a vehicle inspection system said to streamline the assessment process for commercial vehicles. The system can provide a comprehensive overview of a vehicle’s alignment, tyre condition, and brake performance in a matter of minutes. The Quick Check system is designed to increase efficiency and reduce maintenance costs, says Totalkare, allowing fleet operators to identify potential issues before they escalate – thereby ultimately improving vehicle reliability and reducing downtime.

Meanwhile, the Hunter range also includes Heavy-Duty Quick Check, a vehicle inspection system said to streamline the assessment process for commercial vehicles. The system can provide a comprehensive overview of a vehicle’s alignment, tyre condition, and brake performance in a matter of minutes. The Quick Check system is designed to increase efficiency and reduce maintenance costs, says Totalkare, allowing fleet operators to identify potential issues before they escalate – thereby ultimately improving vehicle reliability and reducing downtime.

In addition, Totalkare offers a selection of wheel balancers for light commercial applications. These include the Wheel Balancer 360, said to provide optimal support for wheel balancing with its improved weight tray, tape-weight roller support and 22″ screen.

“Thanks to the automatic program sequence and hidden weight program to place the weight behind the spokes, it allows fast, precise and aesthetic balancing of tyres up to a 30” diameter,” said Totalkare.

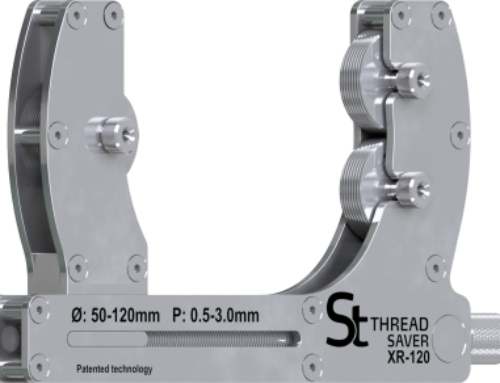

The company also supplies tyre cages to help safeguard against injury in the event of a tyre failure while inflating truck, bus, van and car tyres. They are fabricated from high grade steel with a mesh side panel and a powder coated finish.

Information on the complete tyre and wheel servicing range from Totalkare is available via the website.